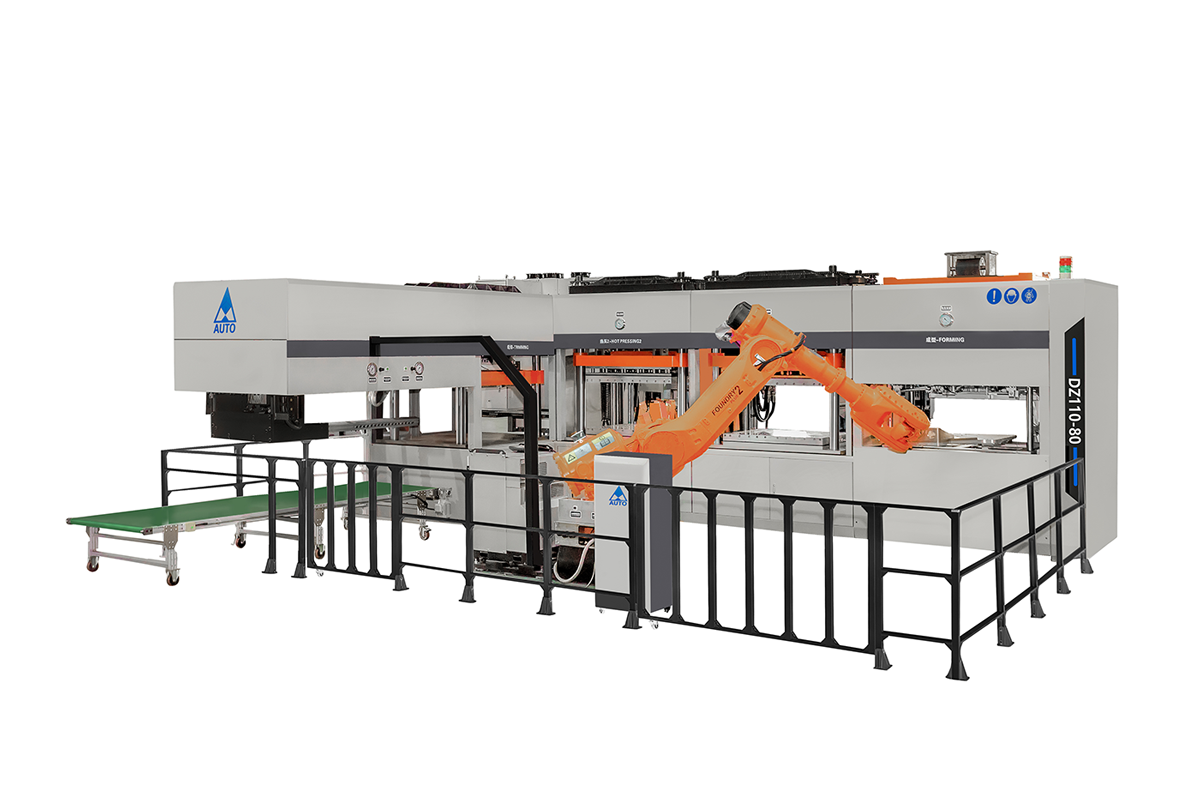

Six Axis Neeg Hlau

Pulp Moulding Tshuab

Biodegradable Tableware Tshuab

Disposable Bagasse Sugarcane Fiber Paper Pulp Tableware Tshuab

Daim Ntawv Pulp Zaub Mov Box Ua Tshuab

Tsis Siv Neeg Daim Ntawv Pulp Phaj Ua Tshuab

| Qauv | 6-axis neeg hlau |

| Hom kev sib sau | Reciprocating txoj kev |

| Formning loj | 1100 x 800 mm |

| Max. Tsim qhov tob | 100 hli |

| Hom cua sov | (192kw) Hluav taws xob |

| Max. Nias siab | 60 ton |

| Max. trimming siab | 50 ton |

| Kev siv fais fab | 65-80 kWh Nyob ntawm seb cov khoom zoo li cas |

| Kev siv cua | 0.5 m³ / min |

| Kev siv lub tshuab nqus tsev | 8-12 m³ / min |

| Muaj peev xwm | 800-1400kg / hnub Nyob ntawm cov khoom tsim |

| Qhov hnyav | ≈29 ton |

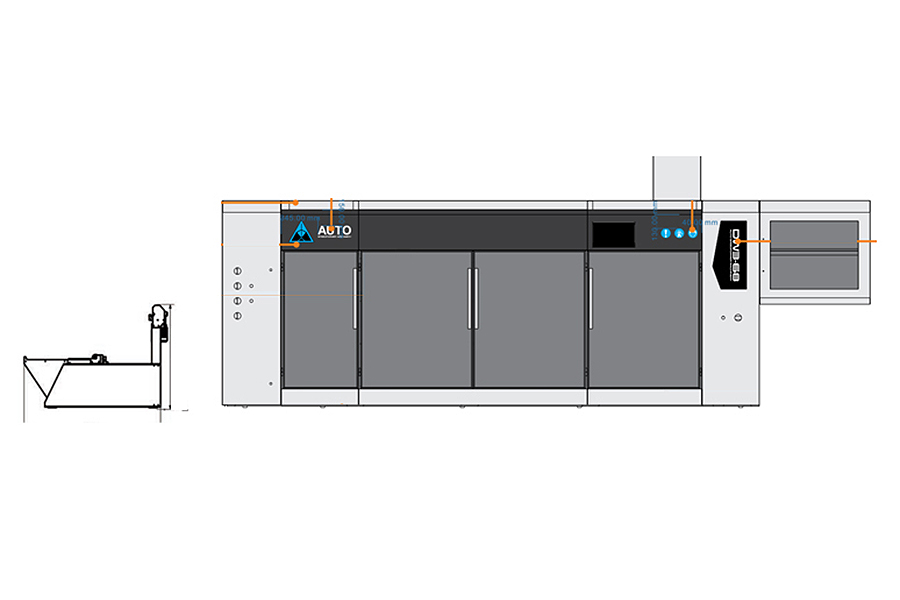

| Tshuab dimension | 7.5m X 5.3m X 2.9m |

| Rated zog | 251 kwv |

| Ntau lawm ceev | 2.7 lub voj voog / min |

♦ Cov ntaub ntawv pov tseg

♦ Daim Ntawv Thiab Cov Tais

♦ Fast Food Take-away Box and Lid

♦ Npaj cov tais ntim khoom noj

♦ Supermarket Fresh Trays

♦ Kev ntim khoom noj khoom haus

♦ Khob thiab hau

♦ Lub khob tuav thiab nqa

1) ntse HMI tswj qhov system, tag nrho kaw-voj ntau lawm.

2) Kev tiv thaiv kev ua txhaum zoo meej: tsis siv neeg nres thiab tswb thaum qee qhov txuas tsis ua haujlwm.

3) Ib qho tseem ceeb los khiav hom ntau lawm.

4) Servo tswj tag nrho lub tshuab, muaj peev xwm ntau lawm, tsis tshua muaj zog siv, txuag hluav taws xob ntau dua 50% thiab muaj peev xwm nce ntau dua 60%.

5) B&R kub tswj: cheeb tsam tswj, txuag hluav taws xob, thaj chaw cua sov hauv 15 thaj chaw nce thiab nqis, teeb qhov kub sib txawv raws li cov khoom 'qhov tob.

6) Lub tshuab tag nrho yog nruab nrog lub cim xeeb thiab cov ntaub ntawv khaws cia ua haujlwm (cov qauv khaws cia thiab xa ncaj qha rau kev hloov pwm). Nws tuaj yeem qhib nrog ib tus yuam sij thiab ncaj qha nkag mus rau ntau lawm.

7) Tsis siv neeg lubrication system (tsis siv neeg lub sij hawm roj mov)

8) Ductile hlau castings ntawm lub platform ua hauj lwm (siab zog thiab tej yam toughness)

9) Lub tshuab tag nrho yog dej tsis qab thiab tiv thaiv corrosion

10) Cov txheej txheem tshwj xeeb thiab cov txheej txheem kub kub, cov pa tawm loj tso pa tawm cov yeeb nkab, zoned kub tswj kom ntseeg tau tias cov cua sov tsis sib xws ntawm txhua qhov hauv kab noj hniav

11) yooj yim pwm loading thiab unloading muaj nuj nqi, humanized pwm positioning ntaus ntawv, zoo heev txhim kho cov efficiency ntawm loading thiab unloading pwm.

12) Lub chaw nres tsheb trimming yog nruab nrog dav dav dav hlau phaj thiab lub tog raj kheej kheej kheej, uas txo cov nqi tsim khoom ntawm cov pwm txiav.

13) Lub tswv yim tshiab hanging manipulator ua kom tiav qhov tsis siv neeg rov ua dua ntawm cov ntaub ntawv ntug thiab cov khoom suav suav.